FOUNDRY & FORGING

Foundries & forge shops typically require a lot of manpower for day to day operations. The harsh environmental conditions are also not preferred by operators and the fatigue sets in after a few hours of continuous duty. For this reason, foundries experience high operator turnover. Foundries are constantly looking for new ways to improve productivity and quality.Foundries & forge shops typically require a lot of manpower for day to day operations. The harsh environmental conditions are also not preferred by operators and the fatigue sets in after a few hours of continuous duty. For this reason, foundries experience high operator turnover. Foundries are constantly looking for new ways to improve productivity and quality.

Foundry specification robots are the preferred option for these conditions. They come with IP 67 protection for the entire arm and can withstand the hot and dusty conditions. They have special seals to prevent dust and micro particles from entering. Heat shields and jackets can be provided to the 4th, 5th and 6th axis of the robots for additional protection. The robot controllers also come with special filters to keep out the dust.

Some of the areas that can be automated in foundries are

Sand Casting - Casting fettling, Sand core handling

Forge shops – Hot and cold forge press tending

PDC – Component extraction, die spraying , component trimming, de-gating and fettling

Investment Casting - Dipping of shell moulds into ceramic slurry, refractory sand coating

GDC – Ladling and part extraction

Aluminium smelters – Ingot handling and palletizing

The benefits of robots is that they are designed to work 24/7 in these harsh conditions. Consistent output means better customer satisfaction. The typical ROI is around 3-4 years. We have an experienced team of engineers who have provided several solutions for the foundry segment. Please share us your requirement and we will be glad to provide a solution.

Get in Touch

Sustainable Automation Solutions

AUTOMOTIVE

We have several years of expertise in serving Tier 1 and Tier 2 automotive suppliers with their automation needs. The auto industry is ideally suited for robots because of the volumes involved.

Typically auto components are produced in high volumes the input component quality is very consistent.

We specialize in the following applications in the auto sector,

Machine tending – CNC, VMC, HMC & IMM

Component inspection

Induction hardening machine tending

Clip insertion

Fastening and dispensing

Machined component deburring & polishing

Assembly automation

We have several satisfied customers in the automotive sector. We understand the ROI demands in this sector and we provide cost effective solutions. We understand the stringent quality and minimal downtime requirements. We have completed several installations where the integration takes place at customer site with interfacing to CNC machines, forging presses and other equipment. We are aware of the limited time available for installation and commissioning. Please share your requirement and we will provide an innovative solution to meet your needs.

Get in Touch

Sustainable Automation Solutions

FMCG

After the automotive segment, robots have the highest presence in the FMCG sector. This includes packaged foods, beverages, toiletries, candies, dry goods and other consumables. These goods are produced in high volumes and require primary, secondary and tertiary packaging at various stages of production. These operations are non-skilled and repetitive. This is where robots are a perfect fit. Also in recent, the FMCG sector has recorded the highest growth in the usage of robots. Robots are only a small part of packaging solutions.

The sucess of a packaging soutions depends on the use of a variety of equipment such as

Vision systems

Transfer, merging and sorting conveyors

Pallet transfer conveyorsand other accessories

Primary Packaging

Food grade robots that can withstand high humidity and washdown are ideally suited for primary packaging applications where unpackaged food needs to be picked and placed to wrappers. These robots typically come with advanced vision based software to eliminate the complex programming.

Our specializations includes:

- Bottle descrambling

- Picking and packaging of food products

- Sorting

Secondary Packaging

Almost all goods need to be packaged into shipping cases for retail sale. Robots can precisely handle multiple SKU’s and changeover times are also quick.

Our applications include:

- Oil can packaging

- Display box packaging to shipping cases

Tertiary Packaging

Shipping cases need to be palletized for transportation to wholesalers and retailers. We offer both individual line and centralized flexible palletizing solutions.

Our solutions include:

- Palletizing of rice, cement, grains and pellets

- Beverage palletizing

- Carton palletizig

Get in Touch

Sustainable Automation Solutions

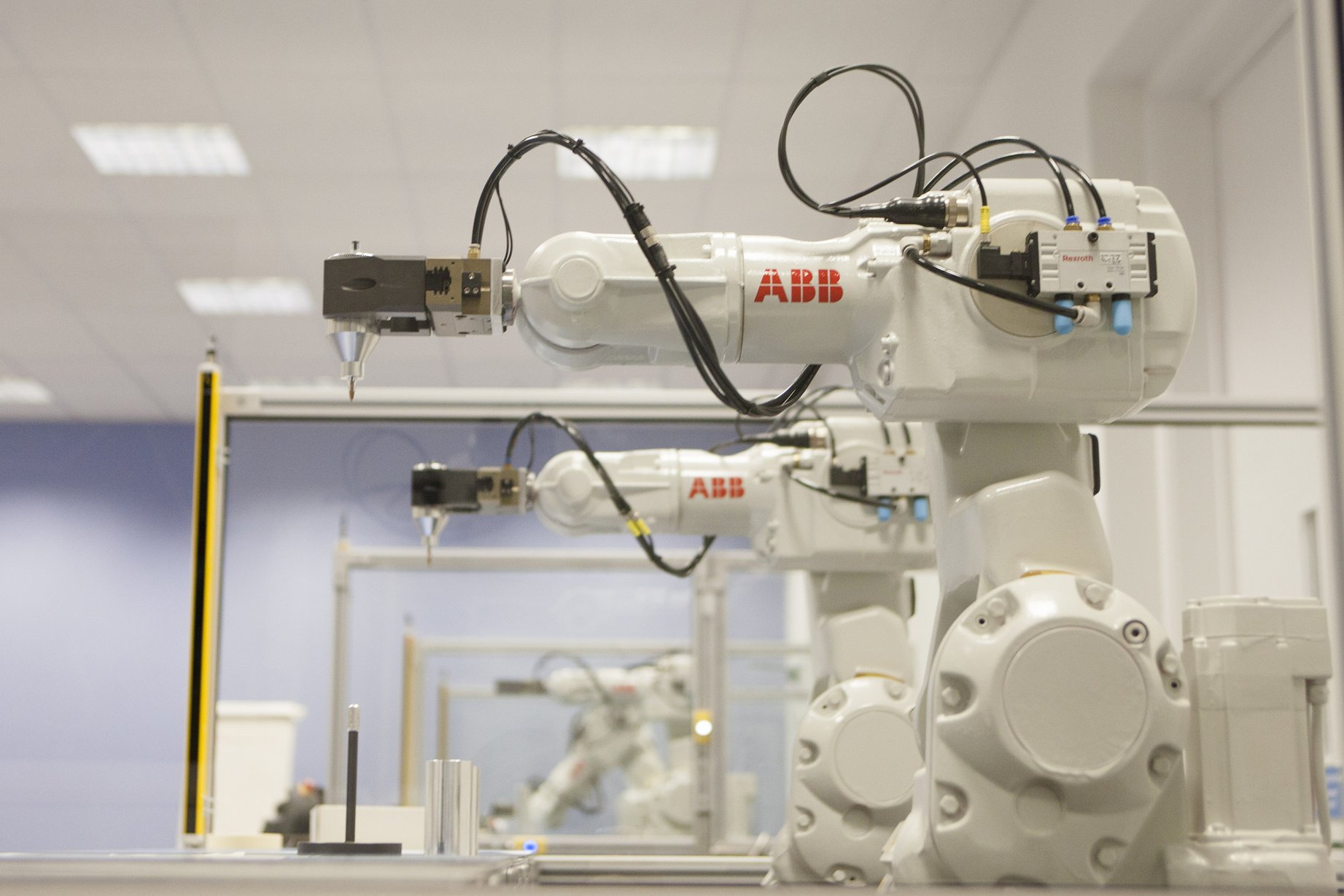

ELECTRONICS & CONSUMER DURABLES

The electronics sector is another prime area for assembly automation and robotics. The volumes are high and the tasks are repeated. Very high precision and high speeds are required to meet the throughput demands of this industry. Cost optimization is also a must in order to remain competitive. Both robots and assembly automation solutions are suited to improve quality and productivity in this sector.

This industry goes though frequent model changes and technology upgrades. Flexible automation is most suited here. Robots are often considered capital equipment and the systems integration components such as conveyors, grippers and fixtures can be changed or modified to suit the model change. The basic design needs to be designed keeping frequent model changes in mind.