INFEED & OUTFEED SYSTEMS

We offer the complete range of infeed & outfeed systems for robotic cells. These systems ensure that the robot is continuously running thus maximizing the cell output. Another important aspect is that the operator who loads and unloads the components is isolated from the robot, thus ensuring 100% operator safety. All systems are proven and are being used by a host of OEM’s and Systems Integrators

Gravity feeders with escapement

Gravity feeders are the simplest and most economical feed systems. They are suitable for shaft type components that roll by gravity. These can be designed with multiple rows to hold a large volume of components. The escapement system can be used to singulate the components are present to the robot. They occupy more space if a large volume of components needs to be stored.

Rotary Stockers

We manufacture precision rotary tables with lifters. They are used for storing a large volume of components for robot pick up. These tables can be designed to hold up to 500kg of components, so that a robotic cell can run un-attended for up to a full shift. These high volume stacker’s are very reliable and require no maintenance. The robot or gantry can pick components from a single point, making teaching tasks simpler. The components need to be stackable, and should not require orientation.

Slide tables

Our LM guide based slide tables are simple to use and can be used if a variety of components are to be fed to the robot. The top fixture sheets can be quickly changed out when a different component needs to be run. They can be configured as a double deck to minimize space.

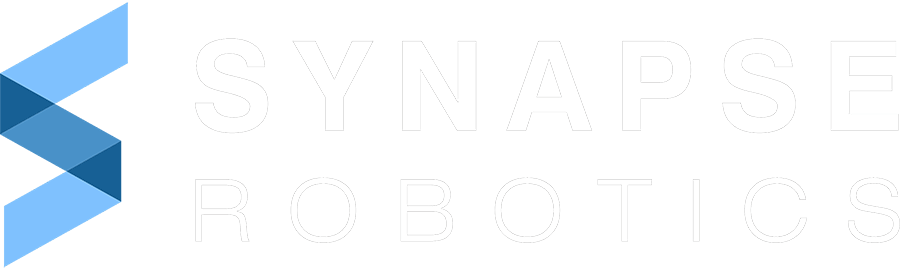

Slat Chain conveyors

Slat chain conveyors are very reliable and precise. A large volume of components can be loaded. They are suited for components requiring orientation. For frequent model changes, the top fixture can be quickly replaced. Quick change mechanisms are provided. Fixture replacement time will be around 15 minutes. This can be done while the set-up change is being done on the CNC machine. These are also maintenance free, except for chain greasing.

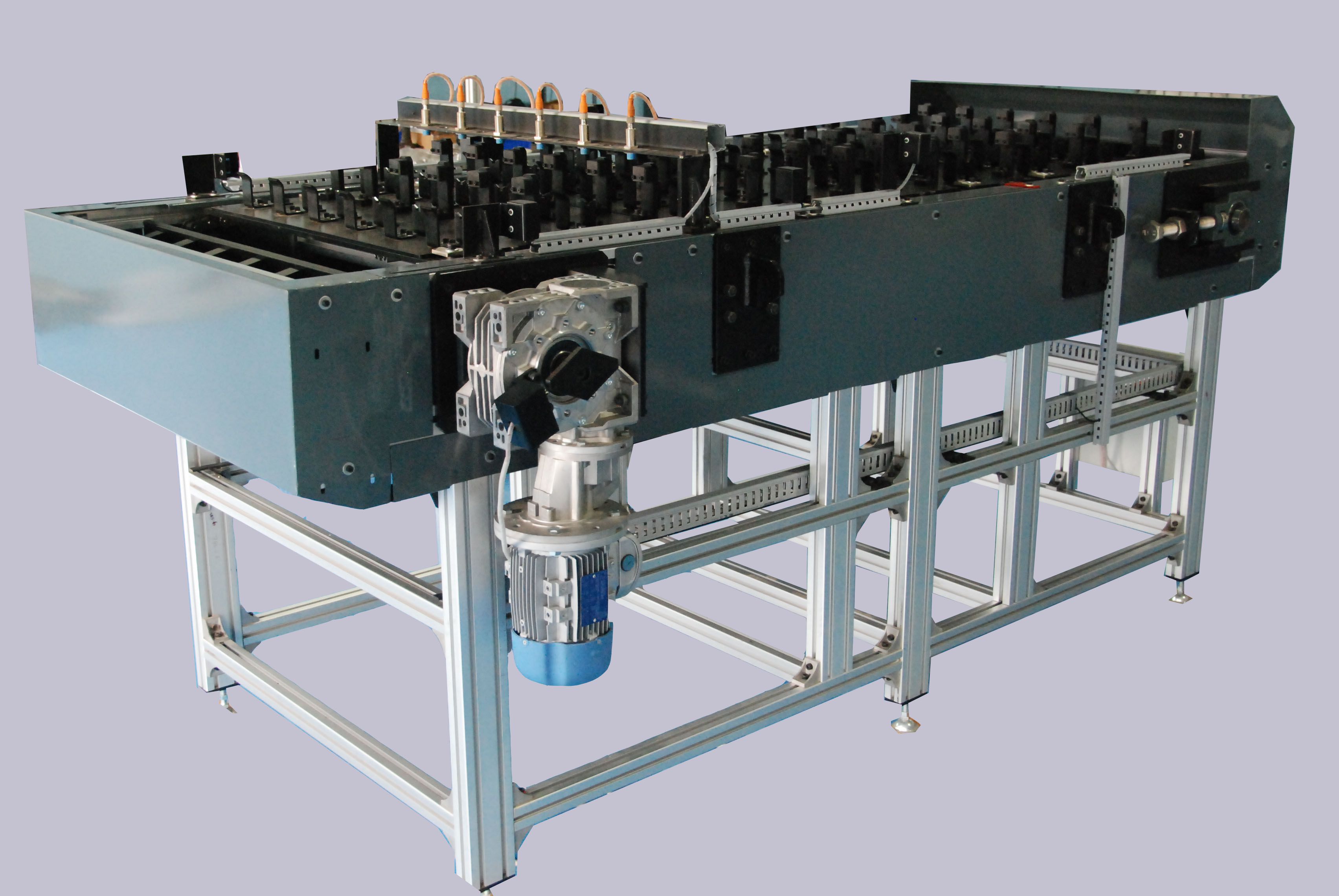

Billet Feeders

Our vertical billet feeders can be used for shaft type components. 200-300 components can be loaded into the hopper. The chain type feeder picks up one component at a time and delivers to the pick point, A robot or gantry system can be used to pick and place components to a CNC machine or forging press. These feeders can deliver a component every 2-3 seconds

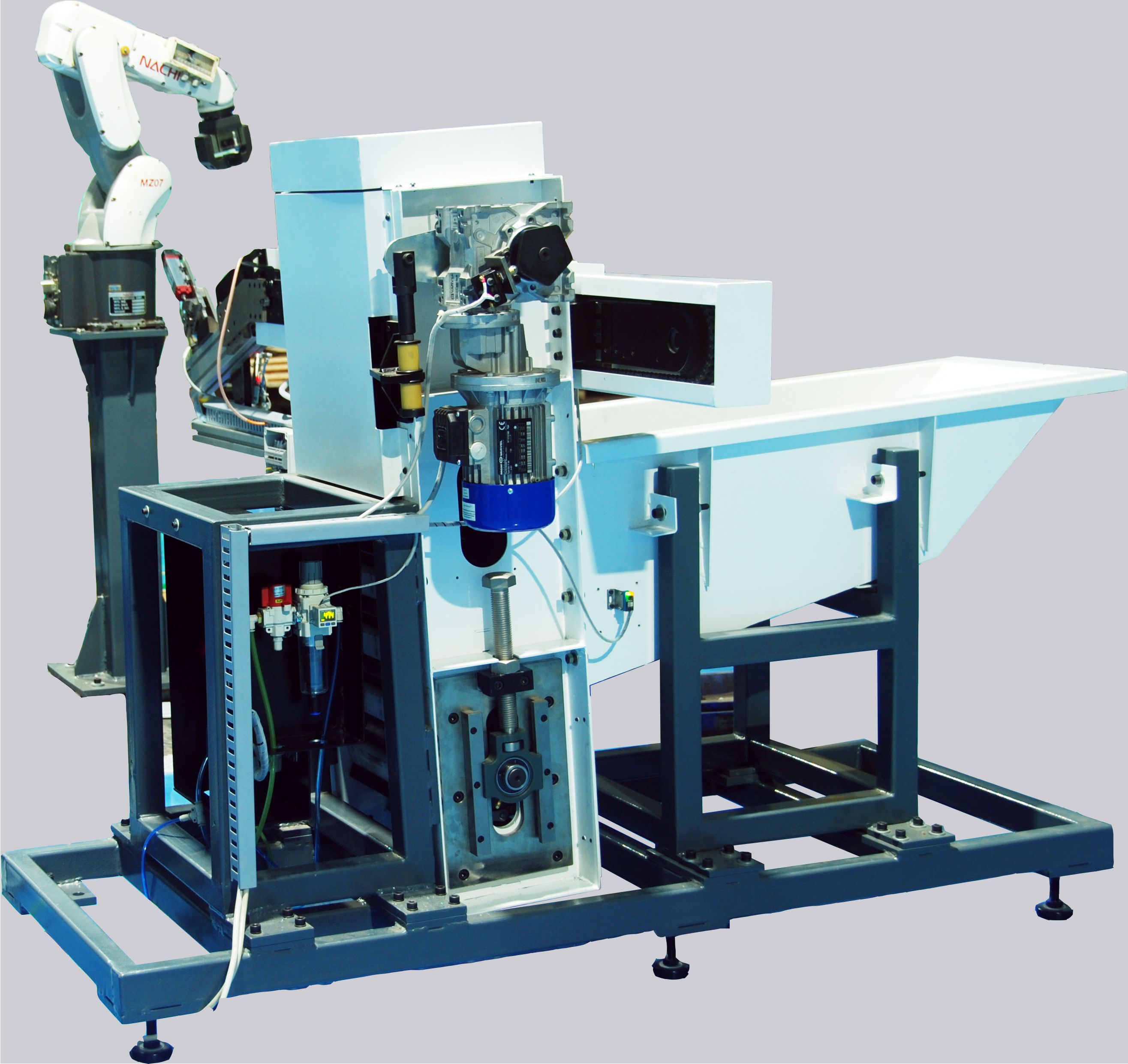

Step/Elevator feeders

For small cylindrical components that cannot be fed using a vibratory feeder (due to damage or noise concerns). Bulk components can be loaded into a hopper. These are suitable where the volumes are high and the feed rate is around 100 components per minute.

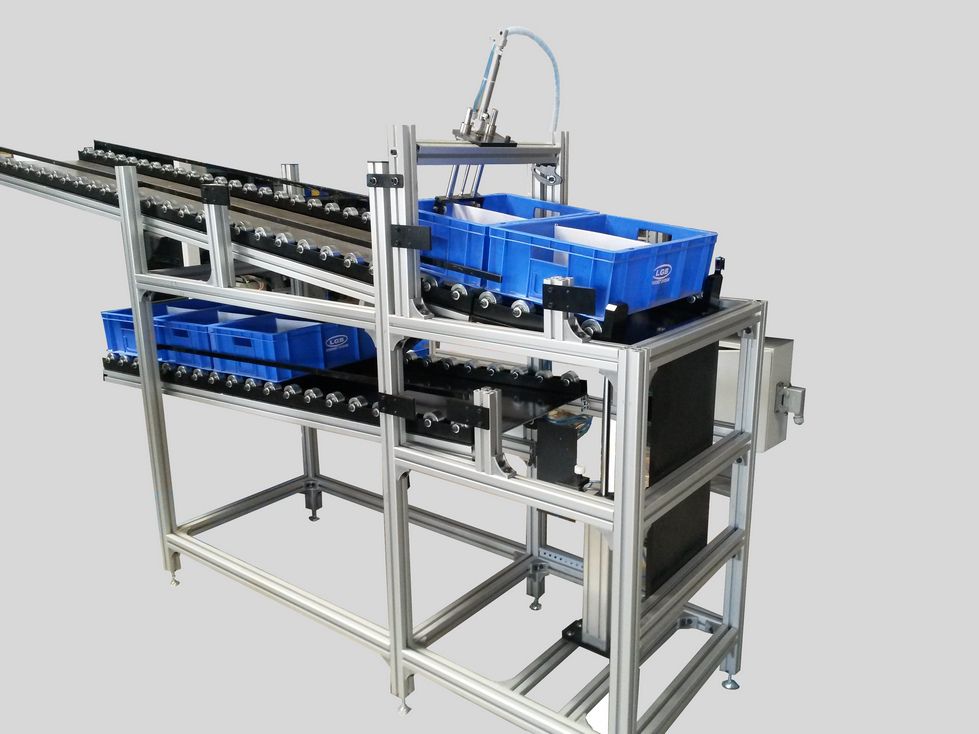

Plastic bin/Crate feeder

We have also developed a unique patented bin feed system for robotic cells. These gravity conveyors can be used to feed empty bins into robotic cells. The robot loads the machined components directly to the bins. Once the bin is full, it is delivered outside the cell, so that operators can safely pick up the bins and move it the next process. This also saves manpower as the task of picking up components from an out-feed conveyor and stacking to bins is avoided. This is a very simple and cost effective solution for robotic cells.

Belt conveyors

We manufacture high quality belt conveyors made of Al profiles. These conveyors can be customized to suit the component weight and material. Length width and height are all made suitable to customer requirements. The conveyors can be provided with simple start stop function or can have individual PLC control with built in sensors. They can be integrated with robotic cells and CNC machines for transfer of parts.