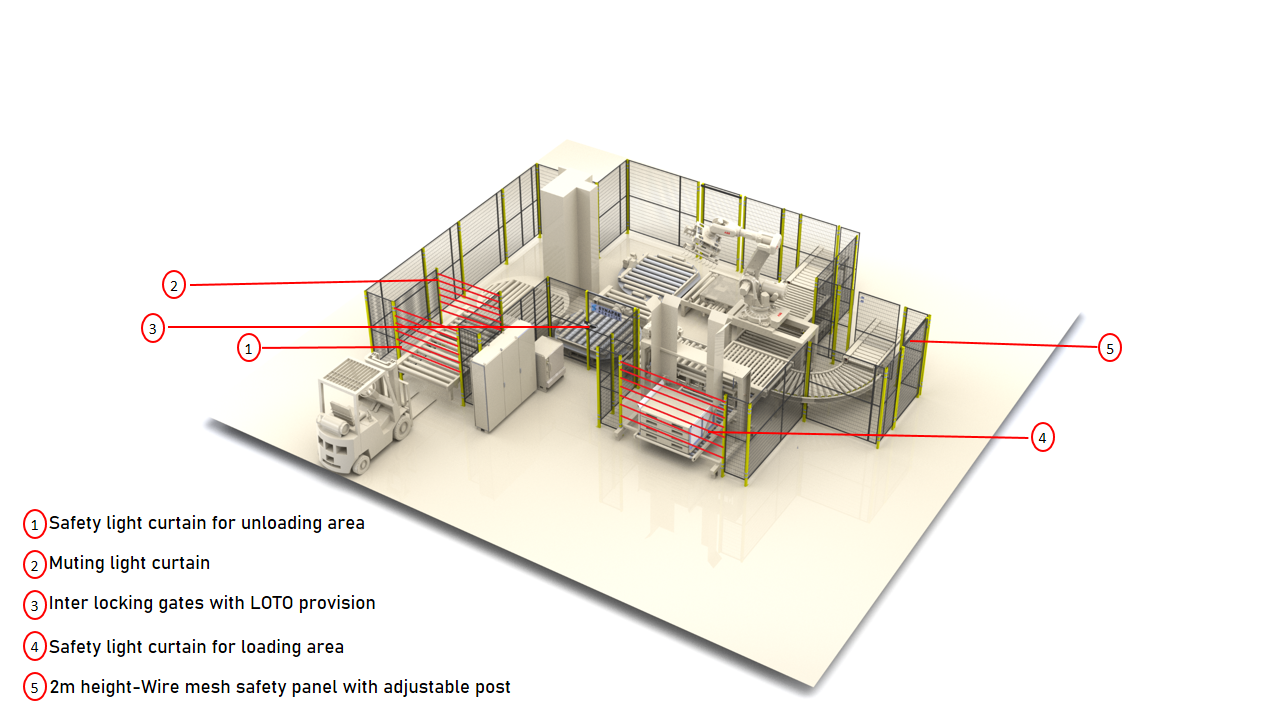

SAFETY IN ROBOTIC SYSTEMS

Safety engineering is an Integral part of robotic systems. Robotic cells are frequently accessed by programmers, operators and maintenance personnel. Accidents and injuries are bound to happen if the required safety systems are not implemented. All our solutions are engineered with full safety compliance. One or more of the following safety precautions are included in all our cells.