Robotic Solutions

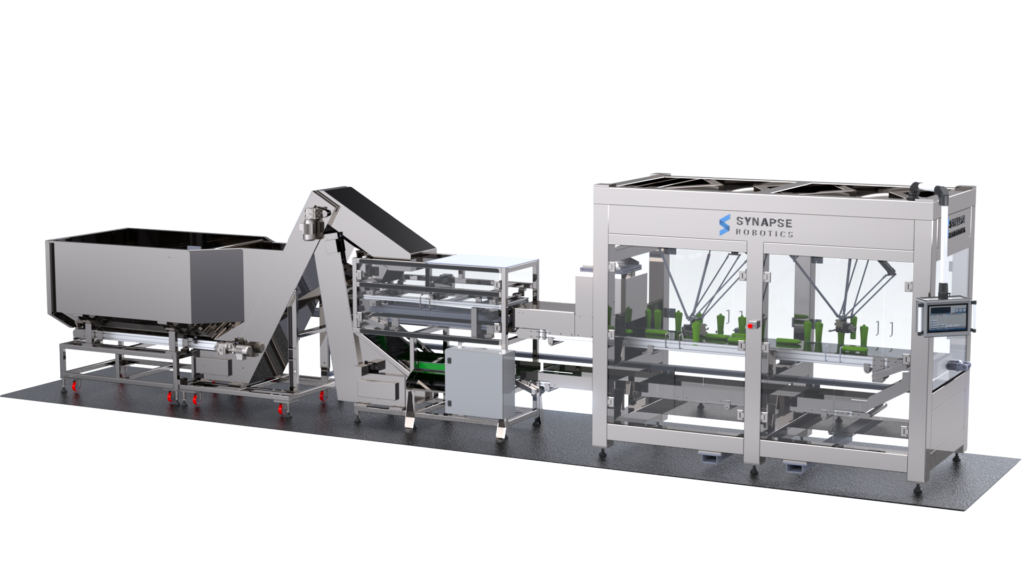

Robots are gaining a strong foothold in both manufacturing & process industries. All major Robot OEM’s have a strong presence in India. Robots fall into the capital investment category similar to CNC machines. With proper periodic maintenance, their lifespan is quite long. Typically minimum 12 year utilization can be expected. Since it is a standard product, robots can be reused if the current application becomes obsolete. Presently due to the unavailability of labour for mundane and hazardous jobs, the use of robots is a must for the Indian manufacturing industry to sustain and grow. At Synapse we offer complete turnkey robotic solutions.

System Integration

What is System Integration?

System Integration is the process of choosing, designing, fabricating and integrating the various components required for the successful operation of a robotic system.

Why is System integration more important than the robot itself?

A robot by itself is a machine similar to a CNC or a VMC. Without the proper selection of cutting tools, inserts, chucks, programming the path and the setting the feed and speed, a CNC machine will not be able to produce the desired results. Given the same CNC machine, if a component drawing is given to two different CNC programmers, one may be able to produce a component with more accuracy, repeatability and better finish, while doing it in less cycle time and managing the tool wear more efficiently. This results in much lower cost per component. This entirely depends on the skill of the technician.

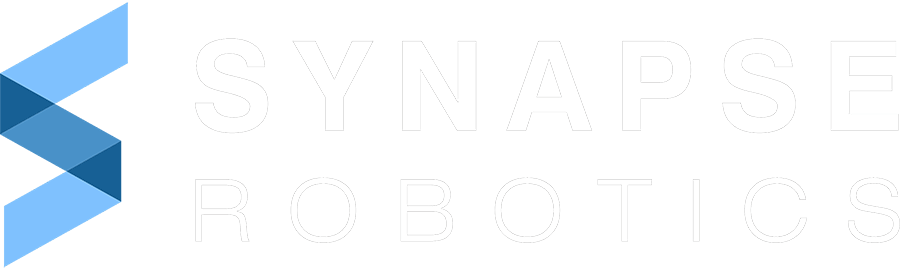

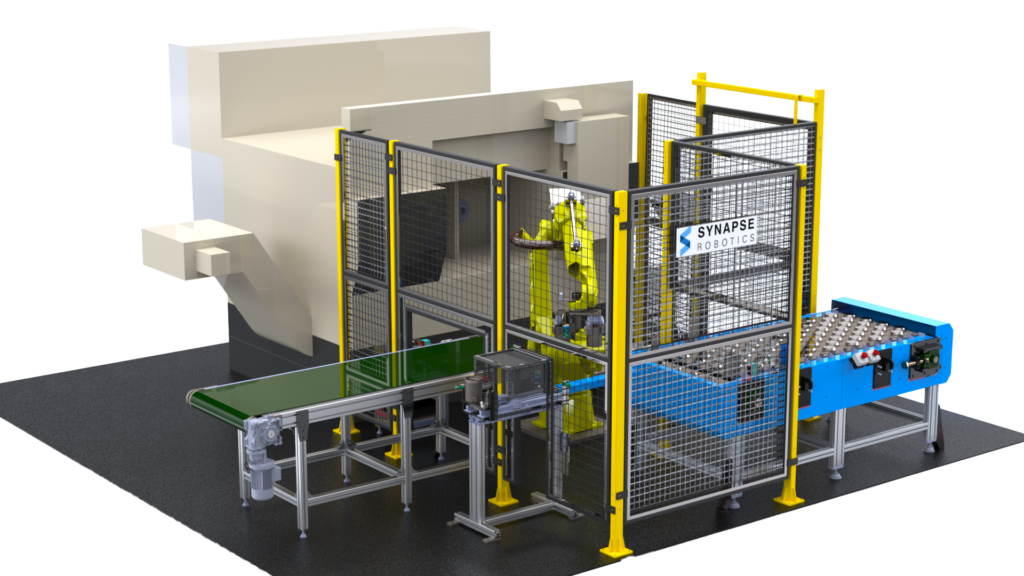

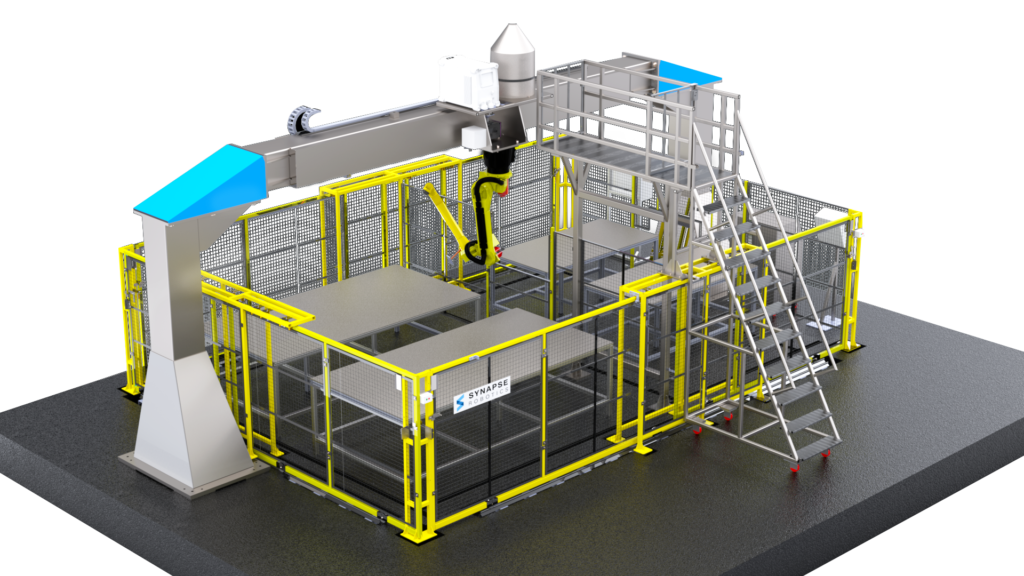

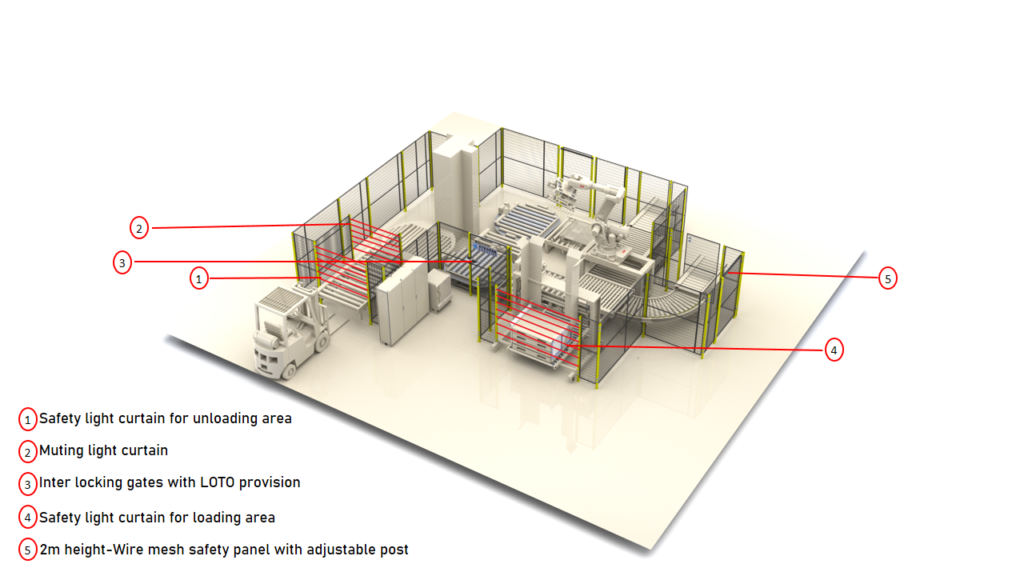

Similarly, a robot by itself cannot do much. The success and operating efficiency of a robotic project depends on the systems integrator who selects and designs the components that make up the whole system. These may include grippers, part infeed and out-feed systems, fixtures, vision systems, safety components, and controls such as PLC or IPC based systems.

Why is customer supplier co-operation important for the success of a project?

Both the systems integrator and customer have to support each other patiently through all phases of the project in order to successfully complete the project.

During the initial design and concept phase, all relevant data should be passed on to the integrator. As the existing manual process is usually established over the years and when an integrator studies the project, the customer may feel that certain data does not have to be passed on. Since the integrator can only spend a limited time on the shop floor some data may be missed during observation. This will result in delays and issues during the installation phase. It is recommended that the entire engineering, production and maintenance teams from the customer side are present for the initial and DAP meetings to provide all possible inputs, suggestions and validate the design. This plays a key role in the success of the project.

During the installation phase, some other issues may crop up. Typically the components may have some variations due to the process. When run manually, they are filtered by the operators. While switching over to an automated system, these issues will be highlighted as the system may not have the intelligence to filter out the variation. This will result in rejections and downtime. Both the integrator and customer have to work together to reduce the variation and improve the efficiency of the system.

Once the issues are resolved, with proper preventive maintenance, a robotic cell will typically produce 20 to 25% more output.

Why is ease of operation and training important?

If an automation solution needs to be sustainable, the operators need to embrace the system. Three key factors play an important role,

The system should be user friendly. This means the user interface on the HMI should be easy to use. All screens required for the operation of the cell need to be thoughtfully designed and placed. The relevant production data should be available and fault messages need to be displayed for easy troubleshooting.

The system should be maintenance friendly and have all the required access.

The team on the shop floor should have the willingness to learn and they need to be trained to run the system efficiently.

Why Choose Synapse as a System Integrator?

Vast experience in providing robotic systems integration solutions for the past 12 years

Our engineers have a keen eye and they capture as much detail as possible during the data gathering stage.

Valuable inputs from all operators to management at the customers side are incorporated into the solution.

We work with OEM’s directly to incorporate the latest technologies into our solutions

Our controls team supplements this with a robust controls system, user friendly HMI interface and IOT/SCADA systems

Our technicians take the utmost care to assemble and integrate the systems with quality and reliability in mind

We guarantee high operating efficiency and definite return on investment.

We have a 100% record in receiving our last 10% retention payments from our customers.

Our service and spare parts revenue is very minimal compared to our competitors.